Surface Treatment

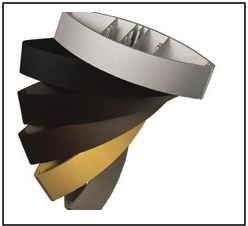

Anodising (Surface Finishing)

Properties & Advantages

Anodised aluminium profiles offer optimum protection against corrosion and are particularly suitable for demanding outdoor applications. Due to the extreme hardness of the anodic layer, the surfaces are unaffected by abrasion and mechanical influences. Beyond durability, anodising preserves the attractive metallic character of the aluminium while providing a dirt-repellent finish.

Capabilities & Finishes

We offer a wide range of decorative and functional anodising options:

- Color Options: Natural (Silver), Black, Gold, and various Bronze tones (from light to dark).

- Mechanical Finishes: Glossy, semi-matte, and matte finishes achieved through satinating, polishing, scotch-brite, sandpaper emery, steel wire brushing, and shot blasting.

- Technical Specs: Customizable coating thicknesses up to 25 microns based on project requirements.

Powder Coating

Properties & Advantages

Powder-coated aluminium profiles provide exceptional resistance to UV radiation, weathering, and corrosion, making them the ideal choice for architectural and exterior construction. This process allows for unlimited color freedom and durable surface protection.

Production Capabilities

Our coating lines ensure high-quality finishes with the following specifications:

- Color Range: Application of all RAL colors with different gloss levels (high gloss, matte, semi-matte, and textured).

- Quality Assurance: Ensuring a homogenous coating thickness along the entire profile surface.

- Capacity: Ability to coat profiles up to 8 meters in length.

- Dimensions: Processing capacity for wide profiles up to 400 mm width.