Aluminium Profile Machining & CNC Solutions

In an increasingly competitive global market, companies need reliable partners to optimize costs without compromising quality. Aludate is your answer to this challenge. We offer end-to-end solutions ranging from high-precision machining on ultra-modern CNC centres to welding, punching, and complete module assembly.

We manage production with highly trained specialist personnel using the latest generation of machinery. Our advanced production facilities, arranged logically over approx. 3,000 m², guarantee a perfectly organized and highly economical manufacturing process. This ensures consistent high quality, short lead times, and optimized production costs for your business.

By partnering with Aludate, you can concentrate on your core business while we handle the complexities of manufacturing. Expensive overtime, high investment risks, and tied-up capital are things of the past.

Technical Capabilities & Processing Services

Our aluminium machining centre offers a wide range of precision services:

- Precision Cutting: Sensitive angular cutting in both X and Y axes, including 90-degree and angular cutting in double-head cutting units.

- Automotive Solutions: Specialized tube and rod-plate cutting lines tailored for the automotive sector.

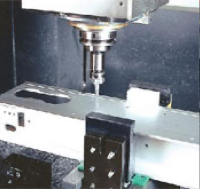

- CNC Machining: Advanced processing capability with sensitive tolerances in 5-axis CNC work centers.

- Pressing & Punching: Punching, combining, and canal opening using hydraulic and eccentric presses.

- Forming & Bending: Precise CNC tube bending and CNC profile bending services.

- Surface Finishing: Emery processes on cut surfaces, chamfering, and protective folio coating.

- Drilling & Threading: Thread opening, countersinking, and CNC lathe work for high-precision diameter tolerances.

Certified Welding & Assembly

- Welding Excellence: TIG (Tungsten Inert Gas) and MIG (Metal Inert Gas) welding performed by WATC (TÜV Nord Accreditation) certified personnel.

- Quality Assurance: All welding processes are certified by WPS (Welding Procedure Specification) and WPAR (Welding Procedure Approval Record) documents from TÜV/Nord.

- Assembly Services: Production of semi-finished or finished assemblies with dedicated sub-assembly lines.

Project Support & Sectors We Serve

New projects are handled with great sensitivity by our specialized engineering staff. We provide full design support and offer alternative suggestions to improve efficiency. Our primary sectors include:

- Automotive Industry

- Electronic Home Appliances

- Electric & Electronics

- Machine Manufacturing

- Construction & Furniture Systems